Structural and mechanical evaluation of the effect of oxygen boost diffusion on a gamma titanium aluminide of Ti–45Al–2Nb–2Mn–1B

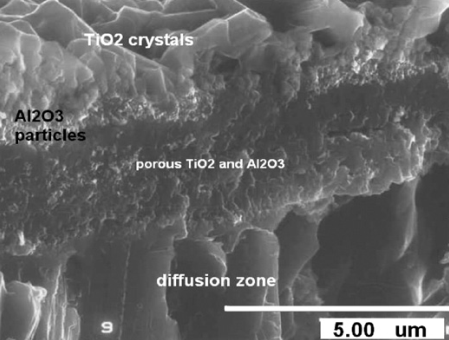

Air oxidation, vacuum heating and a subsequent oxidation (DT treatment) of Ti–45Al–2Nb–2Mn–1B (at.%) titanium aluminide resulted in several oxide layers and a hard Ti3Al as an interlayer between the substrate and the oxide layers.

Surface characterization was carried out using X-Ray Diffraction (XRD), Glow Discharge Spectroscopy (GDS), electron microscopy, microhardness tests, ball-on-disk tests and profilometry.

The compositions of oxides were TiO2 and Al2O3 at the surface layers after final air oxidation and Ti3Al interlayer was enriched with oxygen.

Multi step treatment improved the hardness of treated surfaces significantly in comparison with that of the sample thermally oxidized only at 800 °C (TO treatment). The hard Ti3Al interlayer containing soluble oxygen supported the top oxide layers of the DT treated sample against indentation.

Such supporting layer did not form between the soft substrate materials and the oxide layers of TO treated materials.

The mean value and variation of friction coefficient on multi step treated surfaces were less than that of the untreated material. The friction behavior of worn surfaces on the multi step treated material against steel and WC-Co ball sliders was rather smoother than that of TO treated samples.

Top surface layers of TO treated material were removed at very shorter sliding distances and lower loads than those of DT treated surfaces against both steel and tungsten carbide sliders.

This paper is published in the journal of Surface & Coatings Technology.