Ahmad Reza Rastkar - PhD

Scientist Surface Engineering Wissenschaftler Oberflächentechnik

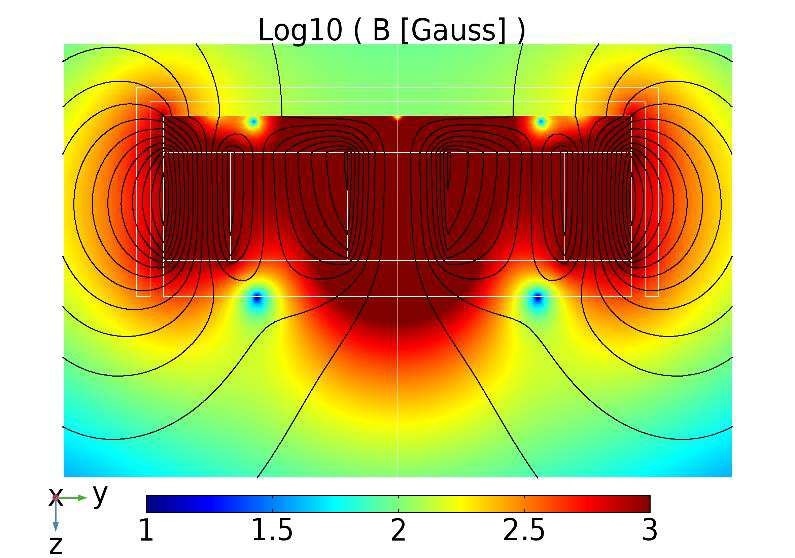

The optical and numerical image of DC plasma glow around a concentric circular magnetron

Work Experience

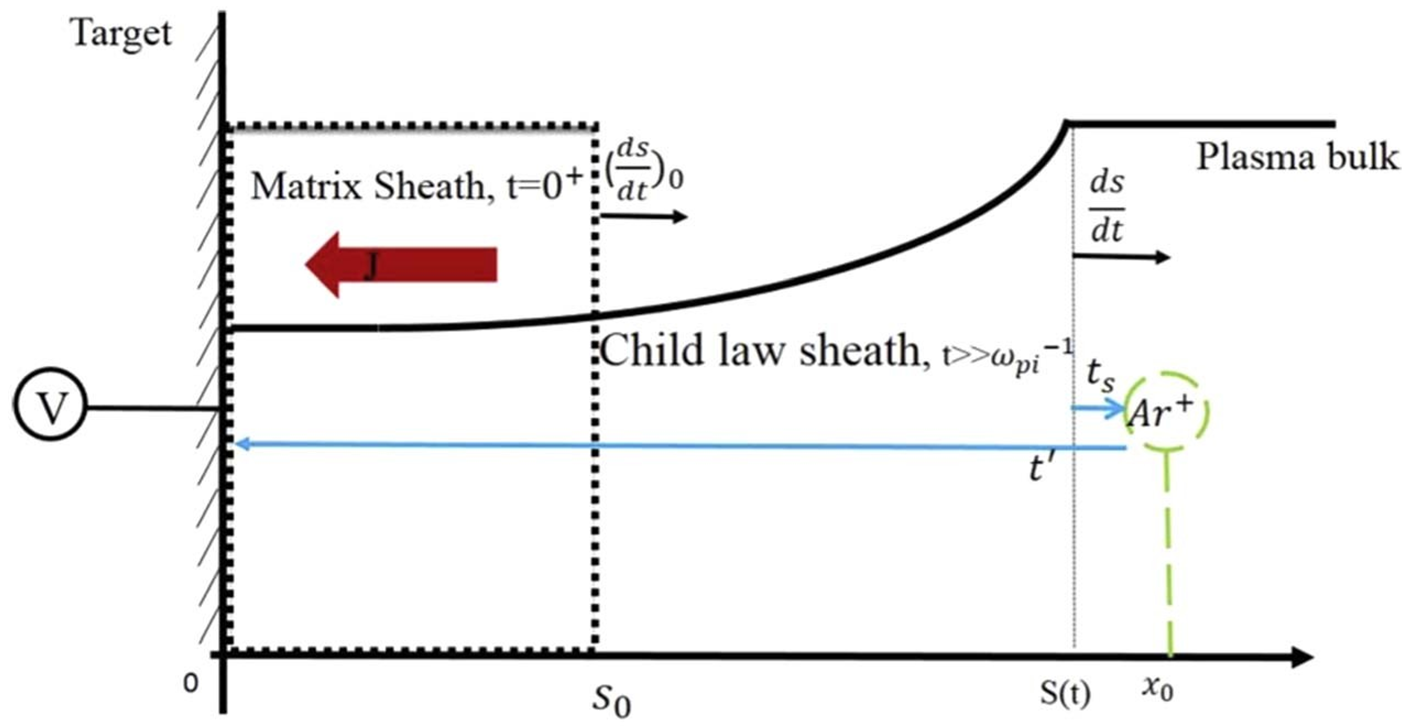

08/2005 – Present Associate Professor / Manager in Materials Science and Engineering Laser and Plasma Research Institute, Shahid Beheshti University, Tehran, Iran ● Editor of scientific papers and technical writing of papers and documents using MS Office (Word, PowerPoint, Excel). ● Analytical and numerical solutions of diffusion-based processes in thermal and plasma enhanced CVD of metallic and nonmetallic materials using Finite Difference Methods (FDM) with Python programming language. ● Responsible participation in setting up and managing the department of Plasma Technology. ● Scientific management of interdisciplinary teams in the field of — Technical writing of scientific reports and papers. — Transfer of the development results from the application-oriented research and technology environment to the pilot series maturity up to the successful implementation in industrial plants for material selection, forming technology, heat treatment, tribology, nanotechnology, welding technology, laser material processing and plasma processes in surface technology, cryogenic technology, thin-film technology and additive manufacturing. — Successful Conception, design and homemade construction of devices in the field of functional surfaces of nitrides, carbides, oxides, diamond-like carbon and nanocarbon products through plasma nitriding, CVD/PVD chemical/physical vapor deposition and cathode atomization/sputtering. — Achievement of applications of plasma discharges for large-area welding, brazing and repairing of steel, aluminum, Ni-super alloys turbine blades and titanium alloys as an additive manufacturing method. — Application of innovative methods for the growth of vertically aligned nanotubes on different metallic and nonmetallic substrate thorough thermal and plasma activated CVD in one Chamber. — Investigation of Analytical and Numerical methods through Finite Difference Methods (FDM) in diffusion based processes of thermal and plasma enhanced CVD. ● Management, implementation, evaluation and presentation of measurements and analyzes for layers and their surface characterization (e.g. hardness, friction, wear, mechanical, optical and electrical properties using light microscopy, SEM, FIB, TEM, AFM, EDS, XPS, XRD, impedance spectroscopy , GDOS, Raman or FTIR, DSC, TGA, micro and nano hardness testing, metallography and non-destructive testing techniques). ● Working experience in the clean room area. ● Teaching the courses of study in plasma surface technology, plasma laboratories, manufacturing processes, physical metallurgy, heat treatment, welding, non-destructive testing technology, advanced material analysis and thermodynamics. ● Supervision of undergraduate and graduate students. ● Experience in applying for and implementing third-party funded projects. ● Recognized reviewer for international scientific journals (Journal of Surface & Coating Technology, Materials Science and Engineering A, Materials Letters). |

05/2022–12/2022, Scientist / Project Manager- Munich – Germany

● Repair, qualification and development of plasma etching systems.

● Plasma etching and production of Hard DLC Nano coatings on Nano-Chip tools through FE-SEM microscopes in clean rooms, OES spectroscopy.

2010 – 2015, Project Manager (part time) – Iran Organization of air Industries , Tehran, Iran

● Design and manufacture of advanced coatings on titanium alloys.

2000 – 2018, Project Manager (part time) – Iran Itok Consulting and Inspection Co., Tehran, Iran, IEI Inspection Co., Tehran, Iran

● Management, training and implementation of Non-Destructive Tests (VT, RT, UT, MT, PT, Phased Array, TOFD), Interpretation of X-ray films and Welding processes.

.

2000 – 2018, Project Manager (part time) – Iran Itok Consulting and Inspection Co., Tehran, Iran, IEI Inspection Co., Tehran, Iran

● Visiting Research Fellowship, supported by the Royal Society of England (Application of Plasma in the control of environmental pollution by using corona and glow discharge plasma in different gases to convert the carbon based species into other products).

PhD in Metallurgy and Materials, Birmingham University, Birmingham, England● Plasma Surface Engineering and tribologyMaster of Engineering, Shiraz University, Shiraz, Iran● Material Engineering (Identification, Materials Selection und manufacturing Processes)Bachelor of Engineering, Shiraz University, Shiraz, Iran● Material engineering (Metal forming) |

|

http://scimet.sbu.ac.ir/AhmadReza_Rastkar https://www.researchgate.net/profile/Ahmad-Rastkar-2 https://scholar.google.com/citations?user=PQwansYAAAAJ&hl=en https://www.scopus.com/authid/detail.uri?authorId=6508022411 |

http://scimet.sbu.ac.ir/AhmadReza_Rastkar https://www.researchgate.net/profile/Ahmad-Rastkar-2 https://scholar.google.com/citations?user=PQwansYAAAAJ&hl=en https://www.scopus.com/authid/detail.uri?authorId=6508022411 |

Selected Papers

https://dr-rastkar.com/the-effects-of-processing-time-on-the-microstructure-and-composition-of-plasma-pack-aluminized-and-oxidized-surface-lay

https://dr-rastkar.com/microstructural-evolution-and-hardness-of-tial3-and-tial2-phases-on-ti-45al

https://dr-rastkar.com/microstructural-evolution-and-hardness-of-tial3-and-tial2-phases-on-ti-45al

https://dr-rastkar.com/effect-of-methane-pressure-on-the-size-of-carbon-nanoparticles

https://dr-rastkar.com/structural-and-mechanical-effect-of-oxygen-boost-diffusion-on-ti-45al-2nb-2mn-1b/

https://dr-rastkar.com/characterization-and-tribological-performance-of-oxide-layers-on-a-gamma-based-titanium-aluminid

● A. R. Rastkar, “Plasma enhanced diffusion of Al-Si alloys on the surface of Ti-45Al-2Nb-2Mn-1B titanium aluminide”, Fifteenth International Conference on Plasma Surface Engineering-PSE 2016, Garmisch-Partenkirchen, Germany, September 12-16, 2016. ● A. R. Rastkar, “Plasma electrolytic process compete gaseous plasma nitriding of AISI 1045 steel”, Twelfth International Conference on Plasma Surface Engineering (PSE 2010), Garmisch-Partenkirchen, Germany, September 13-17, 2010. ● A. R. Rastkar, A. Kiani, B. Shokri, “Effect of pulsed plasma nitriding on Tribological performance of Ck45 steel”, 3 rd International Meeting on Developments in Materials, Processes and Applications of Emerging Technologies (MPA-2009), Manchester, UK, 21-23 July 2009. ● A. R. Rastkar, M. Kabir, M. Amirzadeh and M. Rahimipour, “Effect of pressure on the size of carbon nanoparticles deposited by pulsed plasma enhanced CVD of methane”, Eleventh International Conference on Plasma Surface Engineering-PSE, Garmisch-Partenkirchen, Germany, September 15-19, 2008. |

Industrial Services........................................................................................

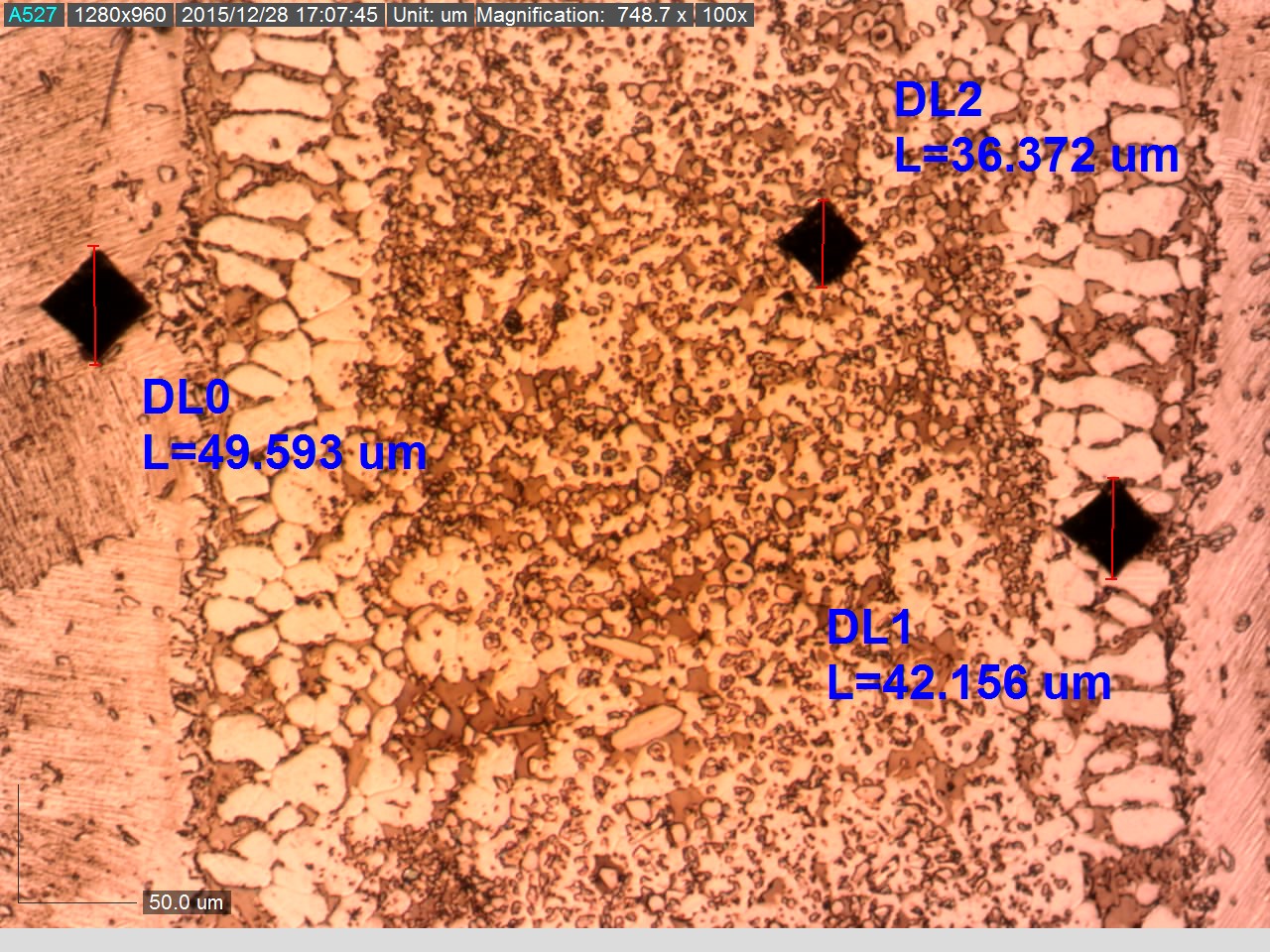

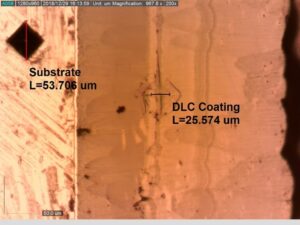

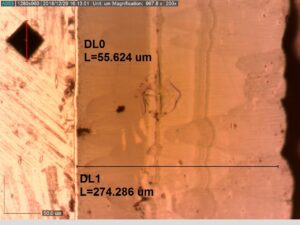

DLC coating on Ti-45Al-2Nb-2Mn can grow up to several tenth of microns by extending Plasma Carburizing to be used as a heat barrier, corrosion and wear resistant coating.

Plasma packed aluminized thick layers on Steels, Titanium Alloys or Aluminides and other Ni-Super Alloys enhance the life time of the corresponding components several times against wear and corrosion.

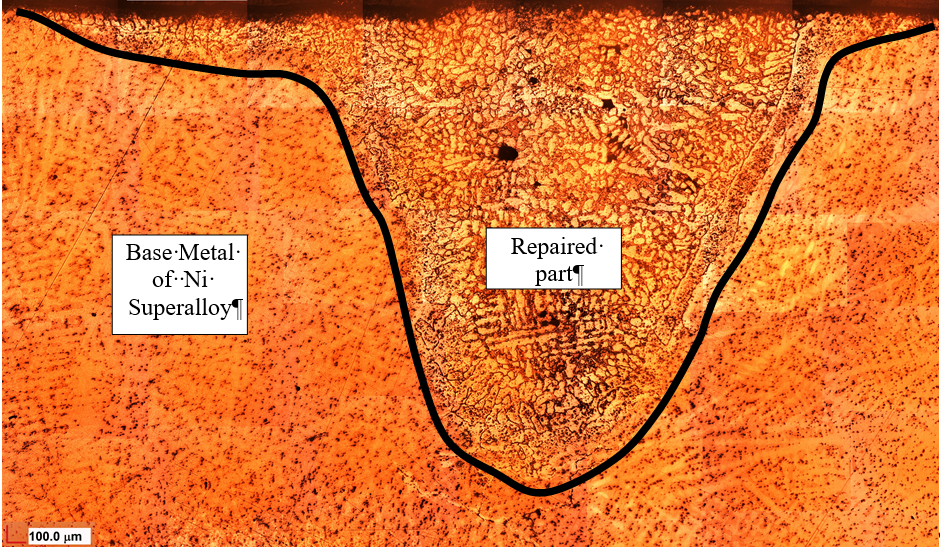

Repair of Ni-Superalloy with application of plasma arc on the powders of filler material added before plasma on the surface and processed in 10 min. No cracking, No nonconformity or adverse effect of welding passes.