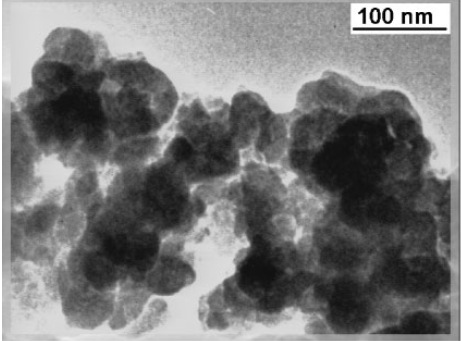

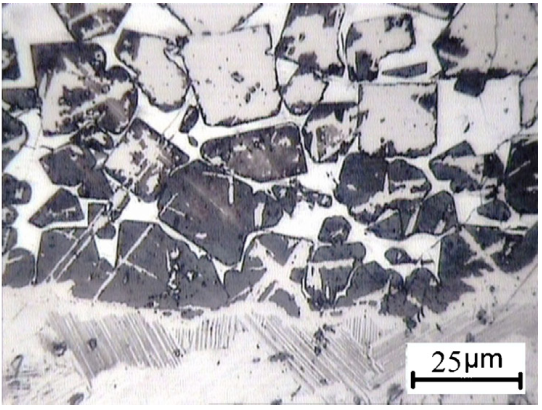

Effect of Methane Pressure on the Size of Carbon Nanoparticles Deposited by Pulsed Plasma Enhanced Chemical Vapor Deposition The nanoparticles of carbon were deposited from methane under the potential of a pulsed direct current discharge. The deposition was carried without external heating. The size, chemistry, and structure of carbon nanoparticles were characterized using transmission electron […]

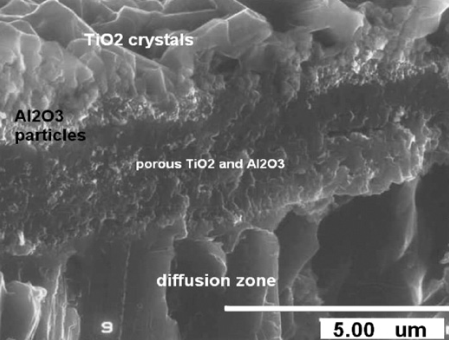

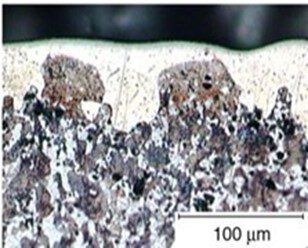

Structural and mechanical evaluation of the effect of oxygen boost diffusion on a gamma titanium aluminide of Ti–45Al–2Nb–2Mn–1B Air oxidation, vacuum heating and a subsequent oxidation (DT treatment) of Ti–45Al–2Nb–2Mn–1B (at.%) titanium aluminide resulted in several oxide layers and a hard Ti3Al as an interlayer between the substrate and the oxide layers. Surface characterization was […]

Characterization and tribological performance of oxide layers on a gamma based titanium aluminide Name* Email* Subject* Your Message* Send Message

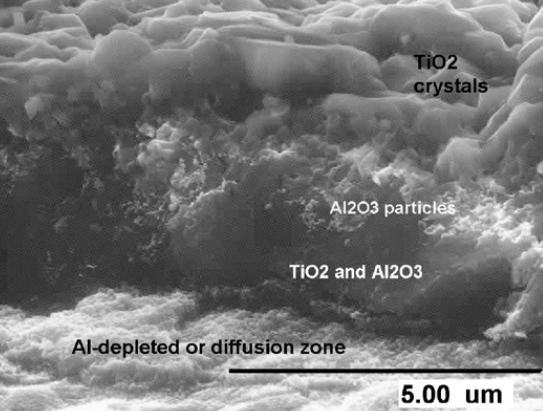

The Effects of Processing Time on the Microstructure and Composition of Plasma Pack-Aluminized and -Oxidized Surface Layers on Low Carbon Steel Low carbon steel was plasma pack aluminized at 973 K (700 C) for 5, 10, and 15 minutes in vacuum of 15 mbar. A paste of aluminum was packed around the samples, and the […]

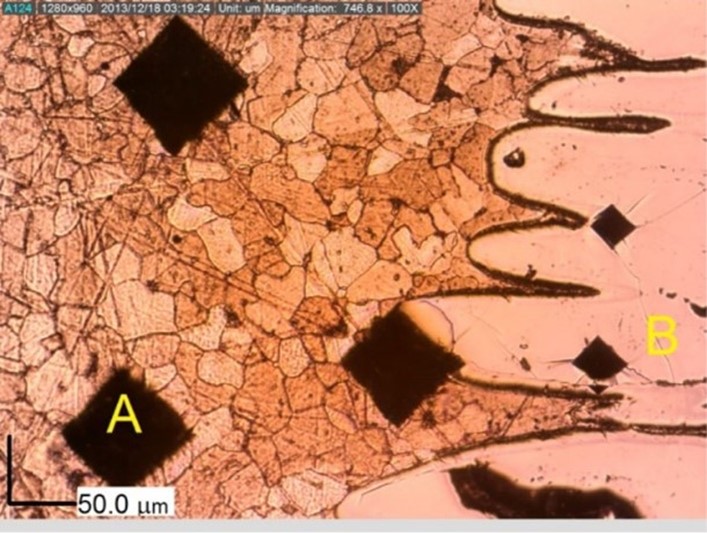

Ti–45Al–2Nb–2Mn–1B was plasma enhanced paste aluminized at 800 °C for 30 min with Al–Si alloys, to investigate the effect of silicon on the structure of coatings and oxidation compounds. Optical and electron microscopy revealed fine and coarse particles of blocky and plate like or needle type particles of Ti5Si3 and TiSi2 phases in aluminum or […]

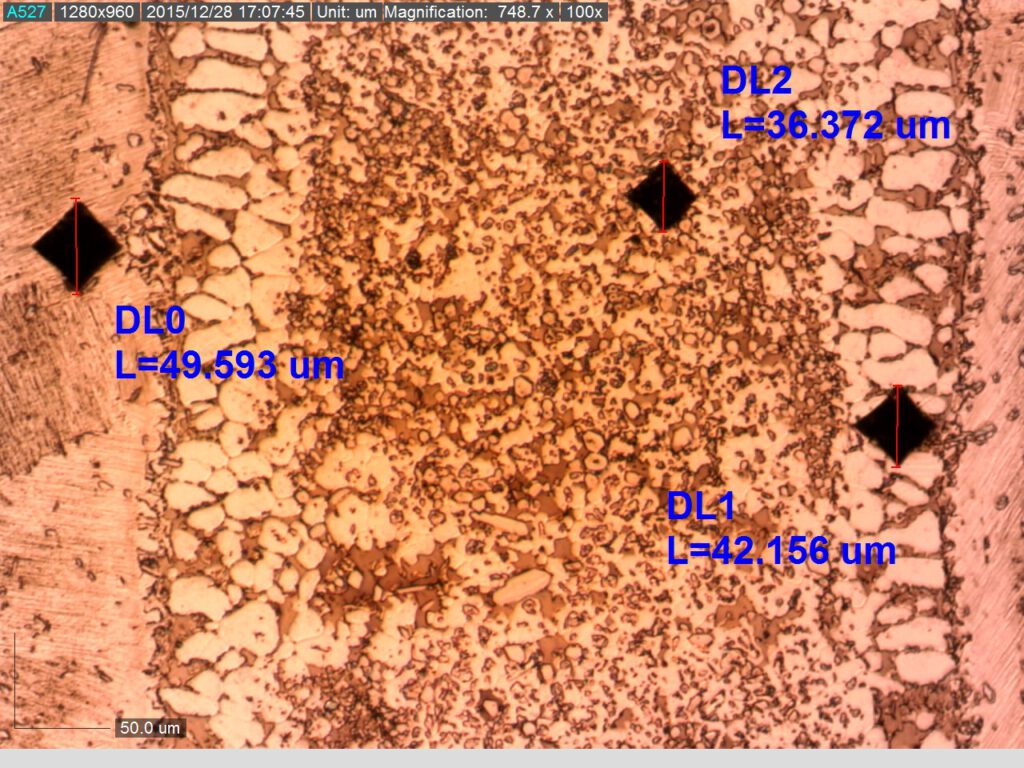

Phase identification and fracture strength of plasma brazed joints of Ti-45Al-2Nb-2Mn-1B with Ti-Ni-Cu filler metals Plasma brazing of gamma based Ti-45Al-2Nb-2Mn-1B titanium aluminide was investigated using Ti-Ni-Cu filler metals. The joints consisted of irregular or equiaxed grain of a2-Ti3Al phases which contained needle-like or fine particles of s3-Al3NiTi2 particles. With increasing Ni from 15 to 25 wt% in […]

surface modification and wear test of carbon steel by plasma electrolytic nitrocarburizing Plasma electrolytic nitrocarburizing (PEN/C) was applied to the surface of carbon steel under the boiling condition of saturated urea electrolyte. In addition to the general effect of the bath temperature, different applied voltages and processing times were also considered in this new process. […]

Time-resolved evolution of collisional transient sheath in plasma source ion implantation In this work, an analytical model for the time-resolved dynamics of the collisional transient sheath in the plasma source ion implantation (PSII) process is developed. The presented model can forecast the temporal dependence of the implanted ion flux and sheath width in the collisional transient sheath. […]

Optical imaging and magnetic field simulation of a DC circular planar magnetron sputtering discharge In this paper, the optical images of glow discharge plasma and the finite element method simulation of the magnetic field strength in a balanced and two types of unbalanced DC circular planar magnetron sputtering sources are presented. The investigation showed that […]