Decomposition of high concentration benzene (produced in paper

and painting industries) and its byproducts, methane, and carbon

dioxide, using plate gliding arc

Rezvan Hosseini Rad & Mohammad Reza Khani & Hamed Mehdikia & Mojtaba Shafiei & Babak Shokri

Abstract

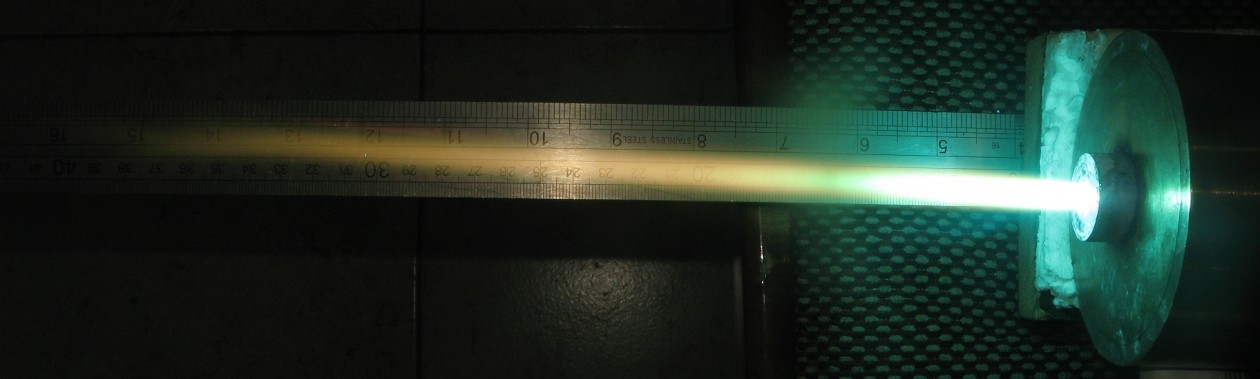

High concentration benzene production in paper and painting industries is a restrictive problem in production line of companies. In this study, removal of high concentrated benzene produced in painting companies was investigated using a Plate Gliding Arc (PGA) reactor. Decomposition of methane and carbon dioxide as the most predominate byproducts of benzene decomposition was also studied using (PGA) reactor. The effect of several parameters such as input power, feed gas flow rate, type of carrier gas, and [CH4/CO2] flow ratio was studied by two series of experiments. The results show significant conversion (>70%) of high concentration benzene (74000ppm) without using any catalyst. Selectivity of CO2 and CO was 88% and 10% respectively showing complete oxidation of benzene. The maximum conversion of CH4 and CO2 reached 52% and 69%, respectively by using optimum ratio of 3:4. The main results of this study proved removal of high concentration benzene using a low-energydensity reactor. Furthermore, an optimum value for efficient conversion of methane and carbon dioxide was achieved and the energy density of the PGA reactor was evaluated, which shows a good promise for industrial applications.