PLASMA JET WORKSHOP

Skin tightening device

New Plasma Lab Products

Fahimeh Darvish, Navid Mostofi Sarkari , Mohammadreza Khani, Esmaeil Eslami, Babak Shokri, Mohsen Mohseni, Morteza Ebrahimi, Mahdi Alizadeh, Chang Fu Dee

Available online 28 November 2019, 144815

https://doi.org/10.1016/j.apsusc.2019.144815

Abstract

Aging phenomenon or hydrophobic recovery of plasma-treated surfaces is a major concern in various fields of application. Post-plasma decay of treatment level can lead to problems such as delamination and incompatibility. Considerable work has been done to understand the fundamental mechanisms of aging, from which several approaches have been developed to tackle it. Most of the released solutions require additional and further steps after or before the plasma exposure to stabilize the treatment level and prevent its downfall. This per se causes process difficulties and increases production costs. Herein, a single-step gliding arc plasma-based method is investigated for modification of biaxially-oriented polypropylene (BOPP). Findings approved post-treatment progressive hydrophilicity improvement in this method. Surface characteristics’ alterations were assessed instantly after the treatment and with intervals during five weeks via ATR-FTIR, XPS, AFM, FESEM, GIXRD, and contact angle measurement (static and dynamic) in order to explain the plasma effects and aging findings. Results indicated that this treatment approach could make a significant contribution to the field of plasma surface treatment via introducing a feasible and fast method that can be carried out in a single step and at the atmospheric pressure with minus aging effects and without the unfavorable hydrophobic recovery phenomenon.

Modifications of protein-based films using cold plasma

Motahareh Hashemi Moosavi, Mohammad Reza Khani, Babak Shokri, Seyede Marzieh Hosseini, Saeedeh Shojaee-Aliabadi, Leila Mirmoghtadaie

International Journal of Biological Macromolecules

Abstract

In this research, the influence of different cold plasma treatments was investigated as a novel method for the modification of protein film properties. The films were prepared from whey and gluten proteins using the solvent casting method and then treated with vacuum low-pressure glow

plasma using air and argon gases at 50 W for 5, 10, and 15 minutes and further analyzed mechanically and physicochemically. The images of atomic force microscopy (AFM) revealed a significant increase in the roughness of whey protein films after plasma treatment, while the roughness of treated gluten films diminished dramatically. Furthermore, the tensile strength of films improved significantly after 10 minutes of process, from 6.902 to 10.772 Mpa and from 1.854 to 2.571 MPa for whey protein and gluten films, respectively. The introduction of functional

groups such as C-O and O=C bonds plus cross-link creation was observed by FTIR which could lead to changes in different film features. Although gas permeability of both edible polymers decreased significantly, other parameters including solubility and water vapor permeability of control and plasma-treated (PT) films did not show dramatic differences. Therefore, the optimum condition and time of low-pressure glow plasma has the potential for modifying protein films.

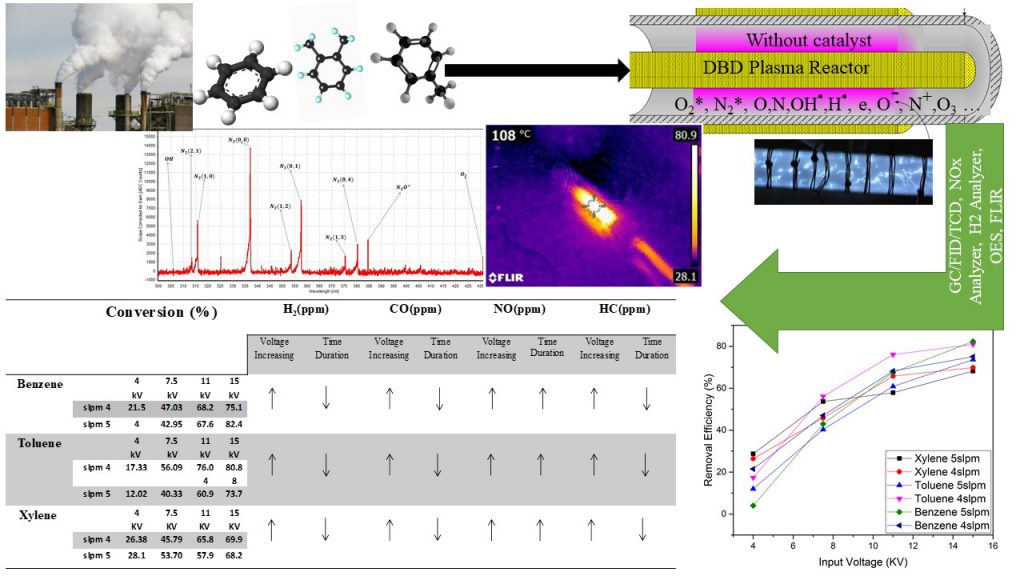

Experimental Analysis of Volatile Organic Compounds Conversion by a Dielectric Barrier Discharge Reactor to Study the main Products: Hydrogen, CO, CO2, NOx and Hydrocarbons

Ali Khadem, Mohammad Reza Khani, Rezvan Hosseini rad, Babak

Shokri, Saied Rashnoo, Barat Ghobadian

Chemical Engineering and Processing – Process Intensification

https://doi.org/10.1016/j.cep.2019.107660

Abstract: In this study, the use of dielectric barrier discharge plasma technology in decomposing the VOCs Benzene, Toluene, and Xylene has been thoroughly investigated. Throughout the experiments, a complete study of factors such as decomposition rate of the reactor, effect of the applied voltage, different types and amounts of the byproducts and also, the temperature of the reactor was carried out. In order to measure the above factors, a thermometer, gas sensors, OES, and GC analysis were used. It was observed that by increasing the applied voltage, the decomposition rates increase, correspondingly. The highest decomposition rates measured for benzene, toluene, and xylene were 82.31%, 80.88%, and 69.68%, respectively. Also, with the increase of voltage, higher decomposition rates were achieved due to the increase of the reactive species’ energy. In addition, it was seen that in the presence of VOCs, CO, CO2 and insignificant amounts of HCs were produced as a direct result of VOCs being decomposed, and there were no NO molecules in the output, in case there are VOCs in the input. Also, optical emission spectroscopy determined the type of reactive species that are responsible for degrading and decomposing the VOC molecules which were excited nitrogen and oxygen molecules.

Shahid Beheshti University

Extended Shelf Life of Chicken Meat Using Carboxymethyl Cellulose Coated Polypropylene Films Containing Zataria multiflora Essential Oil

Z. Honarvar, M. Farhoodi, M. R. Khani, S. Shojaee-Aliabadi

World Academy of Science, Engineering and Technology International Journal of Nutrition and Food Engineering Vol:11, No:8, 2017

Abstract—The purpose of the present study was to evaluate carboxymethyl cellulose (CMC) coated polypropylene (PP) films containing Zataria multiflora (ZEO) essential oils (4%) as an antimicrobial packaging for chicken breast stored at 4 °C. To increase PP film hydrophilicity, it was treated by atmospheric cold plasma prior to coating by CMC. Then, different films including PP, PP/CMC, PP/CMC containing 4% of ZEO were used for the chicken meat packaging in the vapor phase. Total viable count and

pseudomonads population and oxidative (TBA) changes of the chicken breast were analyzed during shelf life. Results showed that the shelf life of chicken meat kept in films containing ZEO improved from three to nine days compared to the control sample without any direct contact with the film. Study of oxygen barrier properties of bilayer film without essential oils (0.096 cm3 μm/m2 d kPa) in comparison with PP film (416 cm3 μm/m2 d kPa) shows that coating of PP with CMC significantly reduces oxygen permeation of the obtained packaging (P<0.05), which reduced aerobic bacteria growth. Chemical composition of ZEO was also evaluated by gas

chromatography-mass spectrometry (GC–MS), and this shows that thymol was the main antimicrobial and antioxidant component of the essential oil. The results revealed that PP/CMC containing ZEO has good potential for application as active food packaging in indirect contact which would also improve the sensory properties of the product.