By Ali Khadem

Abstract

Today, considering the large-scale manufacturing of chemicals, the environment is facing the problem of air pollution more than ever. Problems such as global warming which have appeared due to emission of greenhouse gases and volatile organic compounds from factories and industries, have had deadly impacts on the body of the environment. In addition, the direct impact of these gases on humans has been observed through diseases such as asthma, bronchitis, dyspnea, cancer, heart attacks and different sorts of allergies which devour thousands of lives annually. In order to prevent these pollutants from emitting, various methods with specific upsides and downsides have been used.

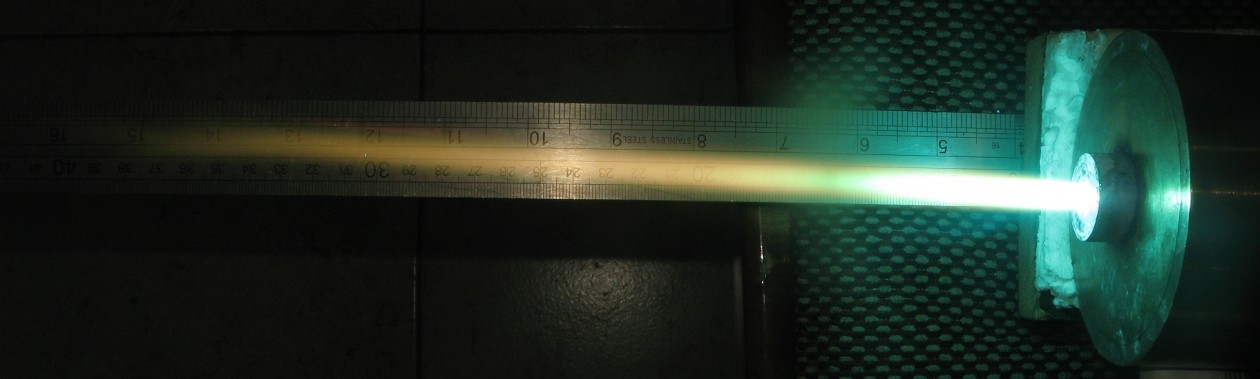

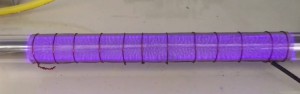

In this study, the use of dielectric barrier discharge plasma technology in destructing the pollutants Benzene, Toluene and Xylene has been investigated. Throughout the experiments, factors like destruction rate of the reactor, effect of the applied voltage, different types and amounts of the byproducts and also, the temperature of the reactor were investigated. In this experiment, vapors of the mentioned pollutants entered the air plasma region inside the reactor by the help help of the carrier gas and were destructed. In order to measure the above factors, a thermometer, gas sensors, OES and GC analysis were used.

The results show that by increasing the applied voltage and the passing of time, temperature rises up to a certain point and correspondingly, destruction rates increase; in addition, high-energy electrons and other active species cause the high destruction of the pollutant molecules. The highest destruction rates recorded for Benzene, Toluene and Xylene were 82.31%, 80.88% and 69.68%, respectively. The major byproducts were CO and H2 and also, other hydrocarbons were produced in small amounts.