Plasma Medicine:

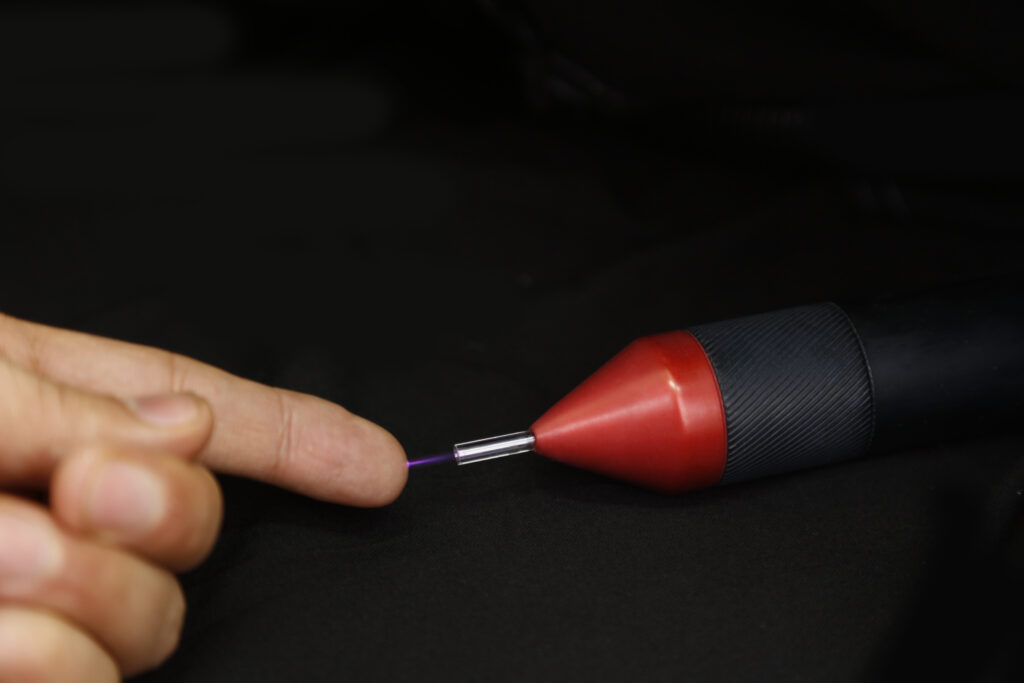

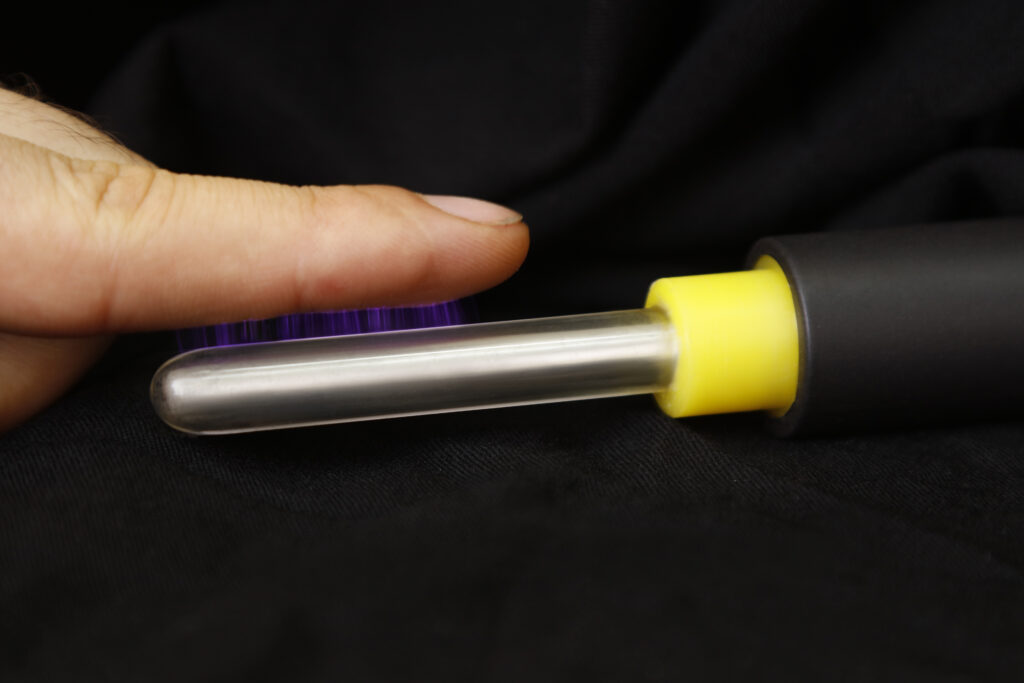

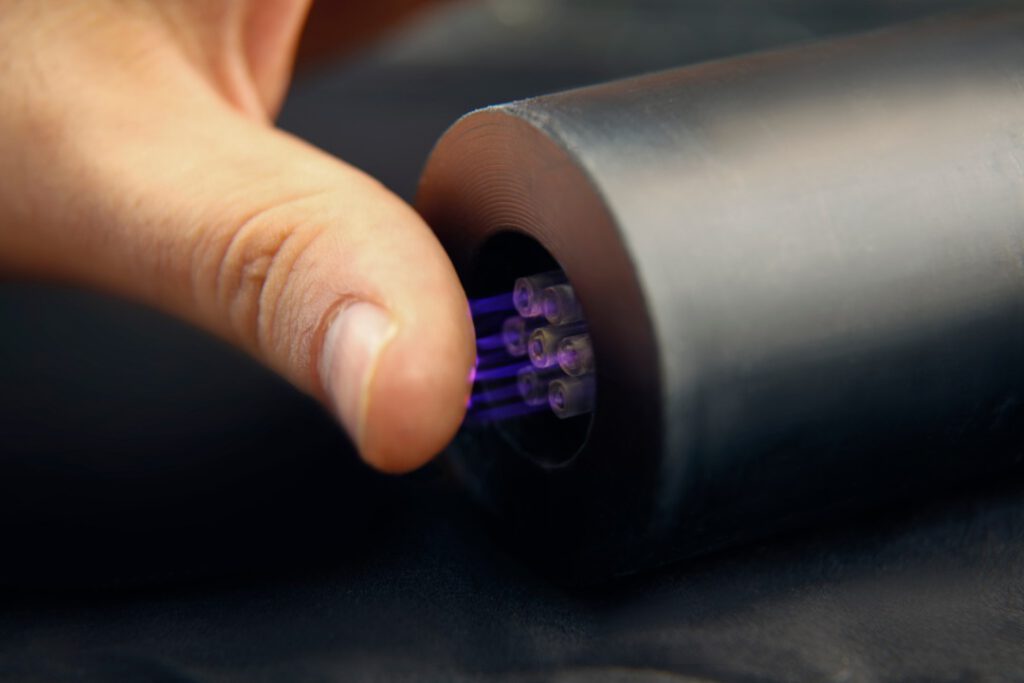

With the expansion of plasma technology applications, we see the performance of plasma technology in medicine. Therefore, one of the main goals of our research group is to set up a medical plasma reference laboratory to develop technical knowledge and expand the applications of this technology. In this project, we are conducting specialized studies in medical plasma in collaboration with four specialized medical research centers and six hospitals. Therefore, more than six plasma systems for various wound treatment applications, skin rejuvenation, dental and cancer applications have been developed in the Plasma Medicine Lab and are currently undergoing clinical studies.

Plasma Pyrolysis and Gasification:

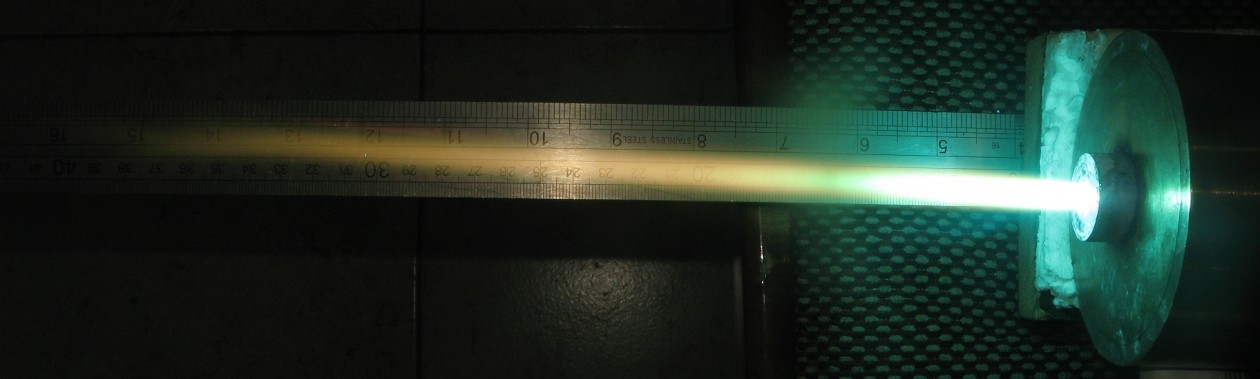

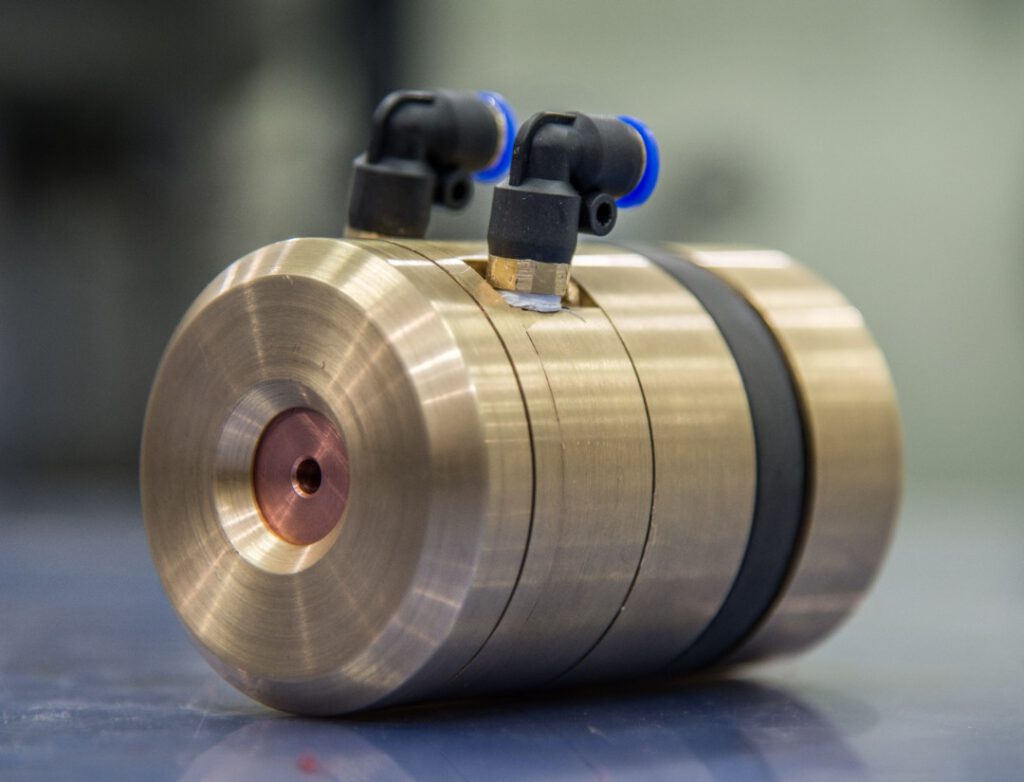

One of our research group’s most important goals is to produce technical thermal plasma knowledge in plasma torches and plasma pyrolysis and gasification systems. More than three generations of plasma reactors have been designed and developed in this field. Therefore, in this center, a liquid waste pyrolysis system with a 20 kg/hour capacity has been designed and built. This system can be used to produce hydrogen and carbon from waste. Our research team is developing experimental data and modeling of this process.

Plasma Technology for polymer and metalized in printing industry:

from many years ago corona devices were using in the printing industry. but according to the recent development in the machine, high speed corona machine is needed. in this projects, we are working to increase the treatment speed on any kind of films and polymers. corona firstly clean the surface and secondly etch the surface to increase the effective surface and finally produce wet able bound on the surface. our aim is to reach the 500 m/min.

The corona system was designed and built in the Plasma Lab of Shahid Beheshti University

Plasma Technology for Surface Treatment:

Surface activation if material by non thermal plasma reactor (Plasma cleaner) is very interesting for different applications.

The Plasma Cleaner system was designed and built in the Plasma Lab of Shahid Beheshti University

Plasma Technology in Textile Industry:

In this project we are going to study atmospheric pressure plasma (Dielectric Barrier Discharge) for treatment textile to increase the wet ability and dying process.this figure shows the industrial scale device for textile with 2.2 m width.

The Industrial Plasma Tex system was designed and built in the Plasma Lab of Shahid Beheshti University

Plasma Technology for polymer and metalized in printing industry:

from many years ago corona devices were using in the printing industry. but according to the recent development in the machine, high speed corona machine is needed. in this projects, we are working to increase the treatment speed on any kind of films and polymers. corona firstly clean the surface and secondly etch the surface to increase the effective surface and finally produce wet able bound on the surface. our aim is to reach the 500 m/min.

The corona system was designed and built in the Plasma Lab of Shahid Beheshti University

The corona system was designed and built in the Plasma Lab of Shahid Beheshti University

Plasma Technology for Surface Treatment:

Surface activation if material by non thermal plasma reactor (Plasma cleaner) is very interesting for different applications.

The Plasma Cleaner system was designed and built in the Plasma Lab of Shahid Beheshti University

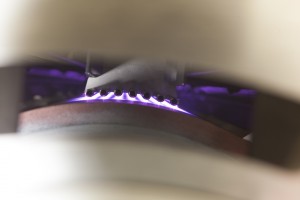

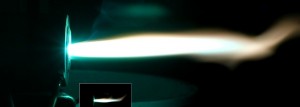

Plasma Technology in Combustion:

In society, especially in our country, fossil fuels, the natural gas in particular, are used outstandingly. In

this project, it is explained that how one can reserve fuel while using the plasma assisted combustion in order to

enhance the combustion efficiency and to reduce the production of dangerous pollutants . A dielectric

barrier discharge torch can change the molecules of fuel and air into free radicals and fragments which are more active than the usual molecules and by this method it can perform the combustion process more efficiently. The

result will be the increase in the temperature, volume and heating power of the flame,decreasing the ignition delay.

Plasma Technology in gas pollutants and odor removal

Today, considering the large-scale manufacturing of chemicals, the environment is facing the problem of air pollution more than ever. Problems such as global warming which have appeared due to emission of greenhouse gases and volatile organic compounds from factories and industries, have had deadly impacts on the body of the environment. In addition, the direct impact of these gases on humans has been observed through diseases such as asthma, bronchitis, dyspnea, cancer, heart attacks and different sorts of allergies which devour thousands of lives annually. In order to prevent these pollutants from emitting, various methods with specific upsides and downsides have been used. in our project we are using the plasma technology for:

- Nox reduction

- Voc conversion

- H2S conversion

- Decreasing the exhaust of burner pollutants.

Plasma Gasification system

Plasma technology is the promising technology for waste management. near to 30 years in the world many company are working on plasma furnace for waste conversion to produce electricite. our team in shahid Bejeshti university is working on many kind if waste such as:MSW, Ash, Petrochemical waste, Hospital waste , …

Plasma Medicine system